designed for: Deboning chicken drumsticks and thighs

Capacity: Up to 2400 pieces per hour

Advantages:

designed for: Deboning chicken drumsticks and thighs

Capacity: Up to 2400 pieces per hour

Advantages:

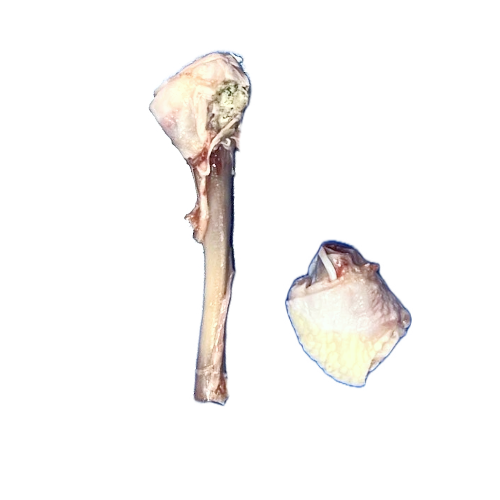

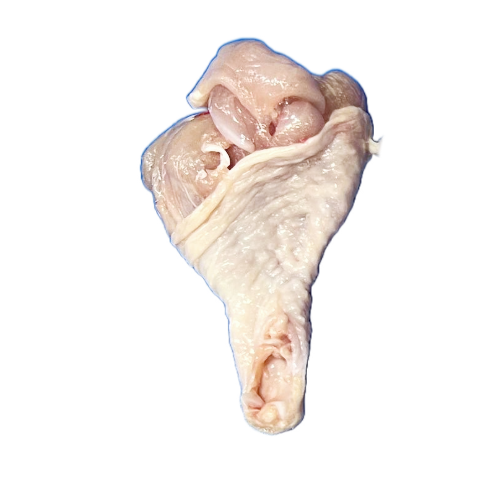

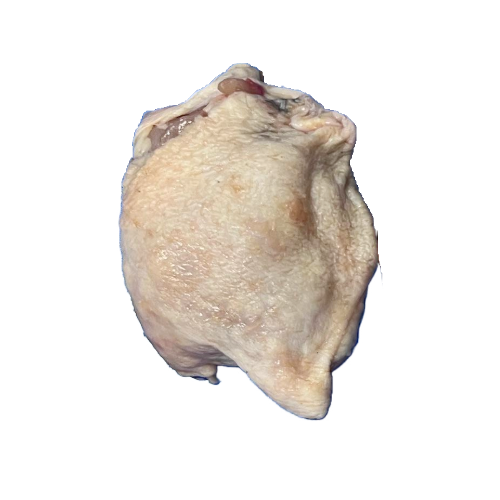

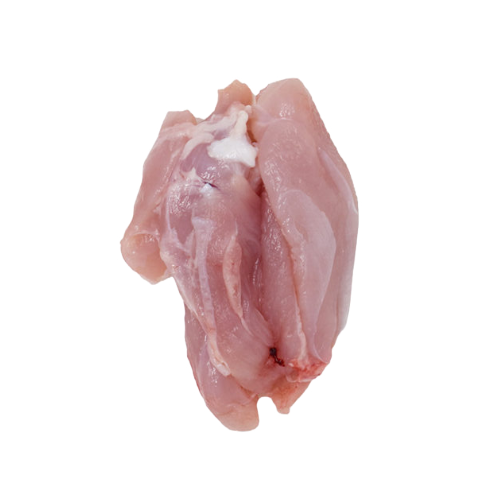

Meet the DrumStick & Thigh Deboner the world’s first plug-and-play deboning system designed for maximum yield and minimum hassle. The DTD12 is specially designed to debone dark meat, meaning thighs and drums, in a cost-effective and efficient manner. The machine is based on the industry-tested “diaphragm” principle. The main parts of the deboning units are a rubber disc with a hole in it – the diaphragm – and a metal shaft which debones the meat. The anatomical cut thighs are placed on the diaphragms. The shaft then extrudes downwards to press the bone out of the thigh. The disc retains the meat, while the bone is pushed through the hole. In this process almost all meat is stripped off the bone, resulting in minimal meat loss during deboning. Efficient deboning allow for greater profitability.

Dutch Poultry Tech’s Drumstick and Thigh deboner (DTD12)

| Model | Article | Thighs per hour | Length | Width | Height | Weight | Installed power | Weight (packed) |

|---|---|---|---|---|---|---|---|---|

| DTD12 | Drumstick and Thigh deboner | up to 2400 | 1500 mm | 1200 mm | 1700 mm | 580 kg | 0.25 + 0.75 kW | 630 kg |

| TD12 | Thigh deboner | up to 2400 | 1500 mm | 1200 mm | 1700 mm | 542 kg | 0.25 + 0.75 kW | 592 kg |

The drum and thigh deboner has a deboning capacity of up to 2,400 pieces per hour. It is a rotating machine with 12 units and 12 diaphragms, designed for safe operation in compliance with modern safety standards. Its construction allows for easy unloading of thighs and drumsticks into crates, bins, or onto a conveyor, while improved ergonomics make cleaning and maintenance quick and simple.

An optional knuckle saw device is available to allow drumstick cutting on the same deboner. Different diaphragm sizes can be used to accommodate various thigh and drumstick sizes, with typical models ranging from 10 to 15 mm. Drums normally require slightly larger diaphragms than thighs. The machine is delivered with a set of 5 diaphragms to help determine the best fit for your processing needs.

Key points:

Handles thighs weighing 80–250 grams per piece (anatomically cut, back-piece removed).

Batch weight range should be within ±15% of the minimum and maximum.

Diaphragm lifespan: ~1 week with properly cut thighs; mis-cut thighs with sharp knuckles or broken bones can tear the rubber and require earlier replacement.

To ensure optimal performance, birds must be cut using an anatomical leg processor or drum/thigh cutter.

The drum and thigh deboner will be delivered with a set of 5 different diaphragms, to test which type suits you best:

Dutch Poultry Tech has many videos available on YouTube demonstrating it’s machines.

The DTD12 Drum and Thigh Deboner from Dutch Poultry Tech is a high-capacity, precise solution for poultry deboning, handling both drumsticks and thighs efficiently. Equipped with multiple diaphragm options, the DTD12 accommodates a variety of sizes and weights, ensuring consistent, high-quality deboning results. Designed with ergonomics and safety in mind, this drum and thigh deboner reduces labor while maintaining product integrity, making it an essential machine for modern poultry processing facilities.

Dutch Poultry Tech is a leading innovator in poultry processing solutions, offering advanced machinery designed for efficiency, safety, and high-quality output. With decades of experience, Dutch Poultry Tech provides complete solutions, including deboners, cut-up systems, and full poultry processing lines. Their equipment is trusted worldwide by poultry processors seeking reliable, ergonomic, and high-performance machinery. From design to delivery, Dutch Poultry Tech ensures your poultry processing line operates smoothly, efficiently, and consistently.