designed for: Deboning Thighs

Capacity: Up to 500 pieces per hour

Advantages:

designed for: Deboning Thighs

Capacity: Up to 500 pieces per hour

Advantages:

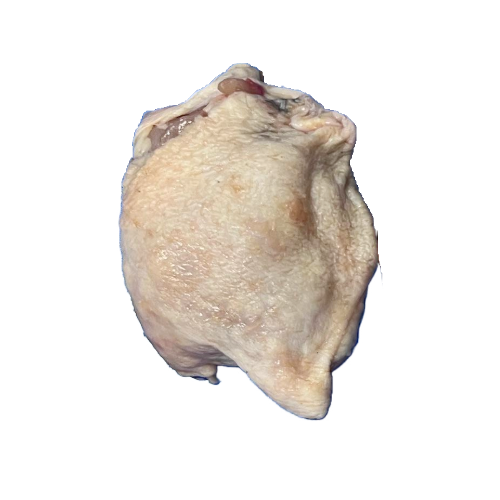

The Single Thigh Deboner from Dutch Poultry Tech offers a simple and efficient solution for deboning poultry thighs and drumettes. This compact machine operates solely on compressed air, requiring no electricity, which makes it easy to install and integrate into small to medium poultry processing operations. Using the proven diaphragm principle, the machine removes meat cleanly from the bone as a metal shaft moves downward to push the bone out of the thigh or drumette. With various diaphragm hole sizes available, it can process different thigh sizes and achieve a capacity of up to 500 pieces per hour.

Dutch Poultry Tech’s Single Thigh Deboner (STD)

| Model | Article | Thighs per hour | Length | Width | Height | Weight | Installed power | Weight (packed) |

|---|---|---|---|---|---|---|---|---|

| STD | Single Thigh Deboner | Up to 500 thighs | 450 mm | 240 mm | 700 mm | 17 kg | Only compressed air needed -10 Liters per thigh | 29 kg |

The Single Thigh Deboner from Dutch Poultry Tech is a compact and efficient solution for deboning poultry thighs and drumettes, ideal for processors looking for a reliable and easy-to-integrate machine. Designed for small to medium poultry processing operations, this unit operates entirely on compressed air and does not require electricity, making installation simple and flexible.

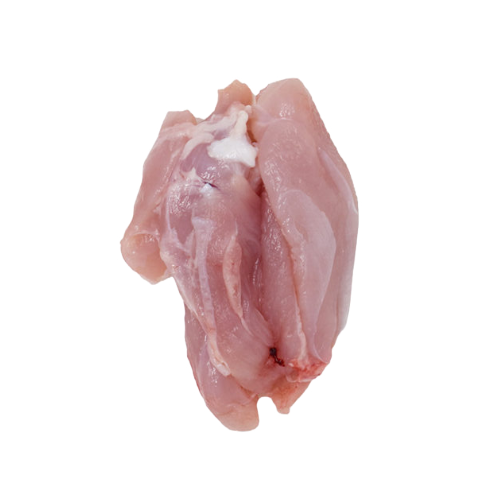

The machine uses the proven diaphragm deboning principle to remove meat cleanly from the bone with minimal meat loss. A metal shaft moves downward to push the bone out of the thigh or drumette, ensuring consistent deboning results. Various diaphragm hole sizes are available, allowing the Single Thigh Deboner to handle different thigh and drumette sizes with ease.

Key features include:

Capacity of up to 500 pieces per hour

Pneumatic operation only, no electricity required

Compact design for easy integration into existing lines

Multiple diaphragm sizes for processing different poultry sizes

Optional: Deboning table with ergonomic switch to operate the machine while keeping the operator’s hands free to handle the thighs

Important note: The legs/thighs must have the back-piece removed; the machine is designed for anatomically cut thighs, not leg-quarters.

For poultry processors requiring higher capacity, Dutch Poultry Tech also offers the DTD12 Drum and Thigh Deboner, a high-performance solution capable of processing up to 2,400 pieces per hour. This machine is ideal for larger operations seeking increased throughput while maintaining consistent deboning quality for both drumsticks and thighs.

The drum and thigh deboner will be delivered with a set of 5 different diaphragms, to test which type suits you best:

Dutch Poultry Tech has many videos available on YouTube demonstrating it’s machines.

The Single Thigh Deboner from Dutch Poultry Tech is a compact and efficient solution for poultry deboning, designed to process thighs and drumettes with minimal meat loss. Using the proven diaphragm principle, this machine operates on compressed air only, making it easy to integrate into small to medium poultry processing lines. Optional features, such as an ergonomic deboning table, improve operator comfort and efficiency.

Dutch Poultry Tech is a leading innovator in poultry processing solutions, offering advanced machinery designed for efficiency, safety, and high-quality output. With decades of experience, Dutch Poultry Tech provides complete solutions, including deboners, cut-up systems, and full poultry processing lines. Their equipment is trusted worldwide by poultry processors seeking reliable, ergonomic, and high-performance machinery. From design to delivery, Dutch Poultry Tech ensures your poultry processing line operates smoothly, efficiently, and consistently.